Problem: Canning line running at 400 Cans / min which is 34% of steriliser capacity.

Work required: Determine what is the true bottleneck of the line & design ways to improve line speed

Desired outcome: Increase the speed of the line by 30% at a cost of less than £10,000

Process steps:

- Identify the true bottleneck of the production line

- Work backwards from the steriliser and look at the waiting time for each process. The process that takes the longest to process 1 batch worth of materials is the bottleneck

- Use stopwatch and measure process time for each piece of equipment and build a line map showing the process time for each step in the production line.

- Bottleneck found to be gravy make-up / mixing as it took the longest to process 1 batch

- Determine ways to increase the speed of the bottleneck within the cost constraints

- In this case, the gravy mixing process was the true bottleneck of the production line

- Mixing time was determined by R&D; this is based on the tank and mixer sizes

- Increasing the mixer size would require a larger tank which would cost more than £10,000

The question then becomes, how to increase the tank capacity and reduce mixing time without incurring huge costs

Some research in to different ways to mix liquids on the internet yielded some great results!

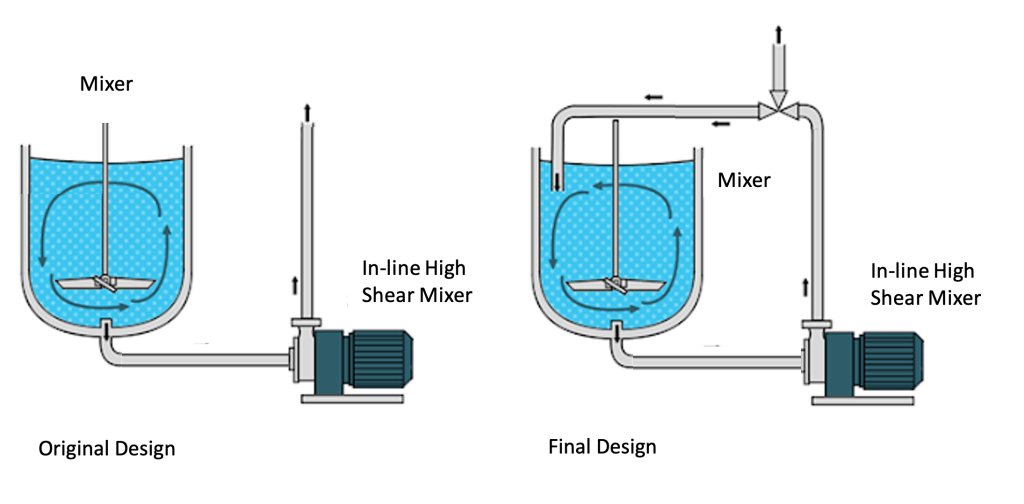

See the original and final equipment designs below:

Chosen solution:

The pumps used to transport the gravy to the next step were also in-line high shear mixers.

The solution to reduce mixing time without having to buy additional pumps / mixers was to use the in-line high shear mixers to recirculate the gravy back in to the tank during the mixing stage. This brought the time for the mixing stage down by over 25%, thus increasing the speed of the bottleneck (and thus the line) by 35%.

The Toal cost to install the changes was under £4,200.